For centuries, man envied birds and their domination over the skies. With the invention of aircraft, we edged our way into the air. Our ambitions, however, did not stop there.

We soared even higher and put a man on the moon and have one of the most advanced pieces of technology in human history in orbit even at this moment – The International Space Station.

Reaching for the skies does come with nearly as many hazards as it does benefits, with gravity being the mastermind of these dangers. Falling is the starkest of them, in league with drops in temperature, high wind speeds, reduction in air pressure, and exposure to radiation.

This has made it necessary for aeronautical and space engineers to come up with safety measures and procedures that need to be followed for both machines and people that intend to mingle among the clouds.

As a modern-day standard for the freight of both people and goods, several steps have been made to ensure the safe arrival of cargo at its destination. Apart from people, the nature of air cargo is precious in nature.

The goods must reach their destination safely, quickly, or both. Travel of any kind would be impossible without the essential component of fuel. High-energy output fuels, such as those used in planes and rockets is extremely volatile, burning at high temperatures and -in sufficient quantities, explosively.

Extreme care is needed when handling these fuels, necessitating the need for compliance control and condition monitoring. Let us take an in-depth look at control conditions and measures in place to make air freight much safer.

Temperature Monitoring

This is the active control and regulation of temperature in a given environment. In the context of aviation, temperature control is pivotal in ensuring goods in transit do not depreciate due to exposure to lower temperatures, a core characteristic of high altitudes.

The activity of temperature monitoring does not require manned operation for most modern systems. The process is instead automated through the use of sensors (which read the temperature of the room or storage location) and actuators -electrical components capable of increasing or decreasing the temperature.

Temperature monitoring and control can be applied for both the plane and the cargo, for instance flowers for the plane, and medical material (like vaccines) for the latter.

Humidity Monitoring

Humidity monitoring is the control and regulation of the moisture content in the air. Like temperature, extremes in humidity can cause water damage (e.g. through corrosion) in excess or dehydration in insufficient amounts. Popular setups for humidity monitoring are configured in sensor arrays spread throughout the cargo storage space.

This is to ensure uniformity in the water content of the air. Humidity monitoring is essential for certain cargo types, such as those with sensitive surfaces like metals or chemicals that can react with the water in the air.

Pressure Monitoring

Pressure monitoring, possibly the most complex to achieve among these three, is the control and regulation of atmospheric pressure in cargo spaces. In aviation, the greater the altitude gained, the lower the atmospheric pressure. This is because the column of air is denser closer to the ground, getting thinner the higher you go.

Pressure monitoring is only possible to completely manage in airtight spaces, as even one small hole can let in or let out gases from the space. Just like temperature and humidity monitoring, pressure control is carried out by automated systems. with sensors and actuators which read and react to conditions according to the set parameters.

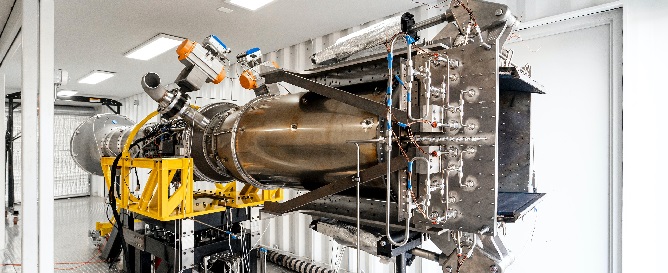

Fuel Storage

Proper fuel storage is essential, because without fuel it may be lost in transit and cut the journey short. Aviation fuel containers must be built with the consideration that they will be operating in conditions different from those on the ground.

As such, manufacturers carry out tests for fuel containers in environments simulating high altitudes. Faulty fuel storage containers pose a major risk to the cargo, vehicle, and crew.

This is because (even at high altitudes with low temperature) jet fuel is highly explosive, and a spark caused by any friction can potentially ignite the entire fuselage.

Therefore, not only should fuel containers be made out of the right materials -flexible to allow for expansion at lower pressure, and heat-resistant, but also be fitted with monitoring components to ensure the fuel status is at the required levels.

CO2 Monitoring

Carbon dioxide monitoring is essential when making it safe for air travel for people and animals. At high enough levels, CO2 is poisonous to animals, in low concentrations causing headaches and drowsiness, and in higher concentrations capable of causing internal system damage and eventually death.

Therefore, it has become essential for all commercial planes to meet standard regulations when it comes to controlling the amount of CO2 in planes during transit, even making it essential to have oxygen masks deployable during an emergency such as cabin depressurization.

CO2 monitoring is done automatically, with sensors built to detect not only CO2 but the concentrations of different gases in the cabin and compensate for any differences by releasing gases from canisters using actuators.

Aerospace Condition Monitoring

Space, the final frontier is one of the most extreme environments that humanity is bravely tackling with the aim of expanding our reach and increasing resources.

The dangers to be encountered make up a long list, composed of hazards such as radiation, (which our atmosphere naturally regulates to habitable levels) extremes in temperature, zero barometric readings, and zero-gravity as well.

With working conditions such as these for astronauts, it is critical that condition monitoring systems are dependable and functional, with several redundancies and fail safes in place in case of malfunction.

Tempgenius is a conditions-monitoring system that provides, sets up, and services monitoring utilities for a large range of applications, beyond aeronautics and engineering.

Research and great care are taken to provide highly customizable utilities with dependable use, with consistent application of innovations and developments to provide quality delivery of service requirements. Reach out to them here and begin the journey to safer and more controllable states of freight for any cargo type.

What Sets TempGenius apart from other Monitoring Systems

A Proven Track Record and Vast Experience

You do not need any random provider for your monitoring; you need a company that works solely on temperature monitoring solutions. It also needs to have a variety of customers and unmatched knowledge. TempGenius has been working on temperature measurement and recording solutions for many years. We take pride in our plethora of partnerships with renowned medical and healthcare entities in the US.

Compliance with the Set Standards

TempGenius temperature monitoring systems are designed and developed to the highest standards. They have met requirements from the CDC, FDA, CAP, ISO 17025, CLIA, Joint Commission (JC), HACCP, and USDA. Furthermore, we provide enterprise temperature alarms and complete temperature logs when Critical Compliance (CCP’s) are out of compliance.

We Provide Certified Calibration Services

With a vast array of software apps and products, we deliver top-notch calibration services that can support validation, traceability, compliance, and quality assurance. Our systems will help you record and monitor deviations and inaccuracies in detail and provide precise results.

Durable and Reliable Systems

Our temperature monitoring platforms are a culmination of robust expertise, cutting-edge technology, and unparalleled experience. Our ultra-stable platforms are created to give you the best performance and durability.

Contact us to customize a Temperature Monitoring Solution for your enterprise.

Give us a call or email us and let’s discuss the most appropriate temperature monitoring sensor for your company.